SG90 Micro Servo Motor | 180° Rotation

100.00 EGP

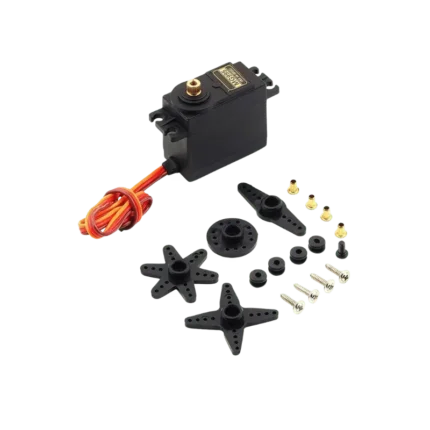

The world’s most popular micro servo for hobbyists and students. Lightweight, affordable, and incredibly easy to control, the SG90 is the go-to choice for small-scale robotics, camera gimbals, and Arduino-based automation projects. Quality assured by Pro Tronix.

Product Overview

The SG90 Micro Servo from Pro Tronix is a tiny but mighty actuator that has become a staple in the maker community. Weighing only 9 grams, it packs enough punch to move small linkages, open latches, or rotate sensors.

Because it operates on a standard 180-degree rotation, you can precisely control its position to any angle between 0 and 180 degrees using PWM (Pulse Width Modulation). It is designed to work perfectly with the 5V output of an Arduino, ESP32, or Raspberry Pi, making it the ideal entry point for anyone learning about motion control and robotics.

Technical Specifications

Feature Specification Weight 9g Dimensions 22.2mm x 11.8mm x 31mm Stall Torque 1.8 kg-cm (at 4.8V) Operating Speed 0.1 sec/60° (at 4.8V) Operating Voltage 4.8V DC (Max 6V) Gear Type Nylon / Plastic Rotation Range 180° Cable Length 25cm Supplier Pro Tronix Key Features

Ultra-Lightweight: At just 9g, it is perfect for weight-sensitive projects like RC indoor flyers or small walking robots.

Easy to Interface: Comes with a standard 3-pin connector (GND, VCC, Signal) that plugs directly into most sensor shields.

Complete Accessory Kit: Includes 3 different servo horns (arms) and mounting screws to fit various mechanical setups.

Great for Learning: The most supported servo motor in terms of online tutorials, libraries, and 3D-printable designs.

Common Applications

Arduino Starter Projects: Learning how to control movement with sensors (e.g., a radar using an Ultrasonic sensor).

DIY Camera Gimbals: Building a pan-and-tilt mount for small FPV or Pi cameras.

Automatic Pet Feeders: Controlling a small trapdoor or rotating dispenser.

Animated Props: Adding eye or limb movements to Halloween props and artistic installations.

💡 Wiring Tip:

Brown Wire: Ground (GND)

Red Wire: Positive (VCC 4.8V – 5V)

Orange/Yellow Wire: Signal (PWM)

In stock

SG90 Micro Servo Motor | 180° Rotation

Product Overview

The SG90 Micro Servo from Pro Tronix is a tiny but mighty actuator that has become a staple in the maker community. Weighing only 9 grams, it packs enough punch to move small linkages, open latches, or rotate sensors.

Because it operates on a standard 180-degree rotation, you can precisely control its position to any angle between 0 and 180 degrees using PWM (Pulse Width Modulation). It is designed to work perfectly with the 5V output of an Arduino, ESP32, or Raspberry Pi, making it the ideal entry point for anyone learning about motion control and robotics.

Technical Specifications

| Feature | Specification |

| Weight | 9g |

| Dimensions | 22.2mm x 11.8mm x 31mm |

| Stall Torque | 1.8 kg-cm (at 4.8V) |

| Operating Speed | 0.1 sec/60° (at 4.8V) |

| Operating Voltage | 4.8V DC (Max 6V) |

| Gear Type | Nylon / Plastic |

| Rotation Range | 180° |

| Cable Length | 25cm |

| Supplier | Pro Tronix |

Key Features

-

Ultra-Lightweight: At just 9g, it is perfect for weight-sensitive projects like RC indoor flyers or small walking robots.

-

Easy to Interface: Comes with a standard 3-pin connector (GND, VCC, Signal) that plugs directly into most sensor shields.

-

Complete Accessory Kit: Includes 3 different servo horns (arms) and mounting screws to fit various mechanical setups.

-

Great for Learning: The most supported servo motor in terms of online tutorials, libraries, and 3D-printable designs.

Common Applications

-

Arduino Starter Projects: Learning how to control movement with sensors (e.g., a radar using an Ultrasonic sensor).

-

DIY Camera Gimbals: Building a pan-and-tilt mount for small FPV or Pi cameras.

-

Automatic Pet Feeders: Controlling a small trapdoor or rotating dispenser.

-

Animated Props: Adding eye or limb movements to Halloween props and artistic installations.

How a servomotor works

- Servo Positioning

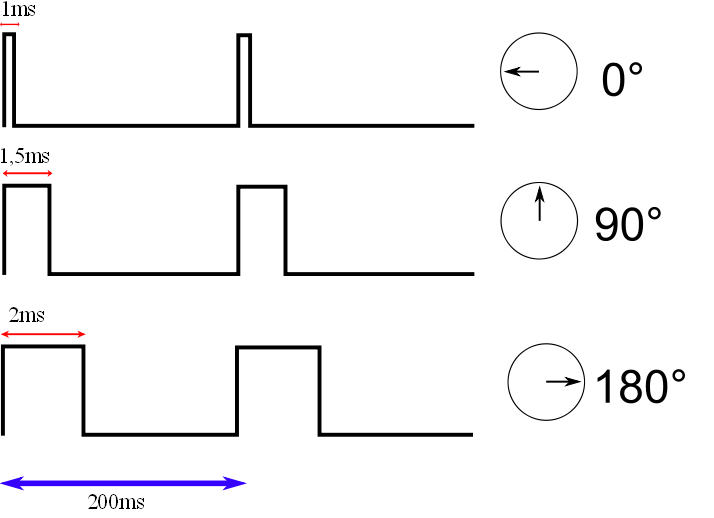

Analog servo motors use PWM, or Pulse Width Modulation, to control the motor shaft position.

The PWM signal is usually about 50Hz, which is a period of 20ms. Within that period the pulse width is varied, a shorter pulse positions the servo towards the zero-degree mark while a longer one moves the motor shaft towards the 180 degree position.

The pulse is continually applied to the control lead on the motor, locking the shaft into the desired position.

Pinout of Servo

| Wire | Color |

|---|---|

| Power | Red |

| GND | Black or brown |

| Signal | Yellow,orange, or white |

Working Principles

- Signal Reception: The servo receives control signals in the form of Pulse Width Modulation (PWM). The standard PWM signal has a period of 20ms, with pulse widths varying from 0.5ms to 2.5ms to control the angle from 0 to 180 degrees linearly .

- Internal Circuitry: Inside the servo, there is a reference circuit that generates a 20ms period signal with a 1.5ms width. A comparator within the servo compares the external PWM signal with this reference signal to determine the direction and magnitude of the motor’s rotation .

- Motor Control: The control circuit board accepts the PWM signal from the signal line and controls the motor’s rotation. The motor drives a series of gears that reduce speed and transmit motion to the output arm .

- Feedback Mechanism: The output shaft of the servo is connected to a position feedback potentiometer. As the arm rotates, it drives the potentiometer, which sends a voltage signal back to the control circuit board. The control circuit then decides the direction and speed of the motor based on the current position to achieve the target stop .

- Torque and Speed: The 9g servo is designed to be lightweight yet capable of providing significant torque for its size. It can handle a torque of 1.5kg/cm to 2.5kg/cm and achieve speeds within 0.1 seconds to 0.12 seconds for a 60-degree rotation .

- Construction: The servo consists of a high-strength ABS transparent casing, internal high-precision nylon gears, an accurate control circuit, and a high-grade lightweight hollow cup motor, which contributes to its light weight of only 9 grams .

- Control Requirements: To control the servo, a Microcontroller Unit (MCU) must generate a pulse with a period of 20ms, using a high level from 0.5ms to 2.5ms to control the angle of rotation .

- Programming: For programming, such as with Arduino, the servo has three wires: +5V, GND, and a data signal line. The rotation of the servo requires a significant amount of current, so it is recommended to provide power to the servo separately to avoid issues with the mainboard supply .

You can see our available motion control products from here: Motors | Pro Tronix

Shipping & Delivery Policy

At Protronix, we ensure your orders are delivered safely and efficiently through multiple reliable channels tailored to your needs.

Our Delivery Methods

-

Egypt Post: Standard shipping to all governorates across Egypt via the National Postal Authority.

-

Uber Scooter: Fast, same-day express delivery for local orders within supported urban areas.

-

Store Pickup: You can skip the shipping fees by collecting your order directly from our main branch.

You may also like…

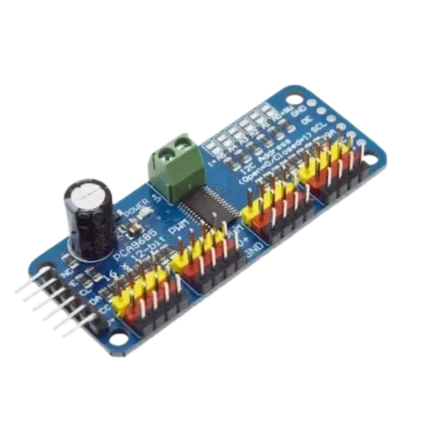

PCA9685 16-Channel 12-bit PWM Servo Driver

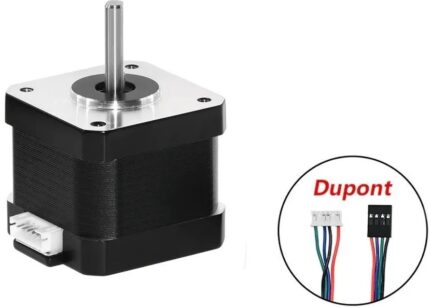

MG995 High Torque Digital Servo Motor | Metal Gear

A heavy-duty, high-torque digital servo motor designed for demanding robotics and RC projects. Featuring a full metal gear train and durable construction, the MG995 delivers the strength and precision needed for large robot arms, steering systems, and heavy-load actuators. Quality assured by Pro Tronix.

MG996R High Torque Metal Gear Servo

SG90 360° Continuous Rotation Micro Servo

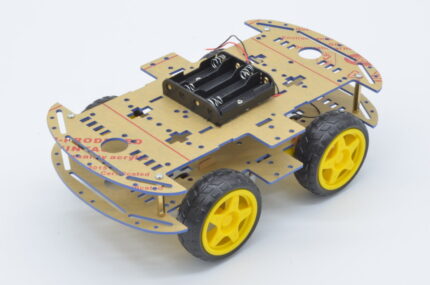

A specialized version of the classic SG90, designed for infinite 360-degree rotation. Unlike standard servos that move to a specific angle, this "Continuous Rotation" motor acts as a miniature gear motor with controllable speed and direction, making it perfect for small wheeled robots. Quality assured by Pro Tronix.

Reviews

There are no reviews yet.